|

|

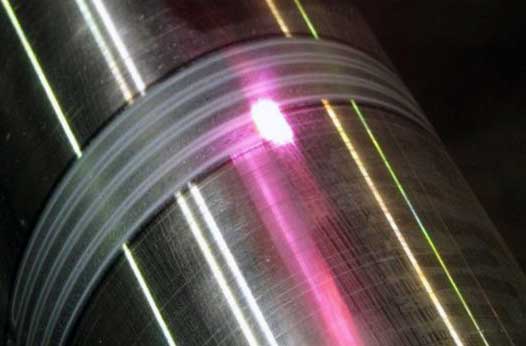

Laser Cladding Services - CapabilitiesLaser Cladding Services, operates 5 axis Laser Cladding machines that can be used to clad shafts up to 6 metres in length and 1.5 metres in diameter, with a maximum weight of 10 tonnes. Our 4 Kw Fibre Laser Cladding Machines have a wave length of 1080nm, which is better absorbed by the base material than other types of lasers, such as CO2 or ND:YAG lasers. The laser cladding machines are 5 axis cladding machines capable of laser cladding shafts or components rotating in the horizontal or vertical axis, as well as complex shaped components. They have 7 metres of travel on the X axis, 0.9m on the Y axis & 1.2m on the Z axis. The 4th axis is A (for rotating shafts) and B (rotates about the Y axis).

Laser Cladding Machines

Capabilities – MachiningLaser Cladding Services is located within Wittenbaker Engineering’s workshop in Henderson, so all pre and post machining processes are performed in-house, saving on time and transport costs. Their large range of lathes, milling machines, horizontal and vertical boring machines, overhead cranes, skilled machine operators and stringent quality controls following ISO 9001 standards will ensure your project will flow smoothly from start to completion. Laser Cladding Services also has access to a range of other machine shops, complete with CNC capabilities, to match any project you may have. Machine Shop Capabilities

Almost all types of metallic components can be laser clad using a large variety of cladding powders, whether it is for wear resistance, corrosion resistance or restoration of worn components, there is likely to be a cladding combination that will have your components and equipment back into service in no time. Base Materials

Cladding Powders

Heat Treatment

Call or email Laser Cladding Services to discuss your laser cladding project. |

|

|

|