Laser Hardfacing

|

Laser hardfacing of a Ball Mill Wear Flange

with 60% tungsten matrix

|

Laser Cladding Services, Perth offers cost effective laser hardfacing solutions that provide high toughness protection for components that are exposed to severe wear applications - tungsten carbide composite overlays are regularly used to protect drilling and mining components, such as laser hardfacing of Hammer Barrels & Drive Chucks. Cobalt-based alloy overlays defend against particulate erosion and cavitation in high-pressure pumps, valves, and turbines.

|

Laser hardfacing of DTH Drive Chucks

for improved wear resistance

|

Laser hardfacing with high-alloy powders, such as Stellite 1, 6, 12 and 21 will enhance the wear properties of components and in almost all cases increase the service life between hardfacing re-application. Using a Tungsten Carbide Matrix with 60% Tungsten will also be beneficial in increasing wear resistance and component life span, as it produces an almost indestructible outer layer against the most abrasive wear environment.

|

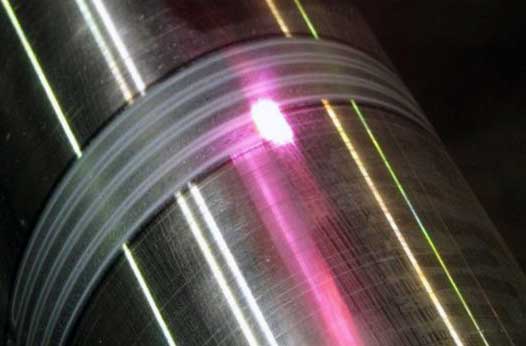

Laser hardfacing of DTH Hammer Barrels

with 60% tungsten. Capable of in excess of

25,000 meters of drilling

|

|

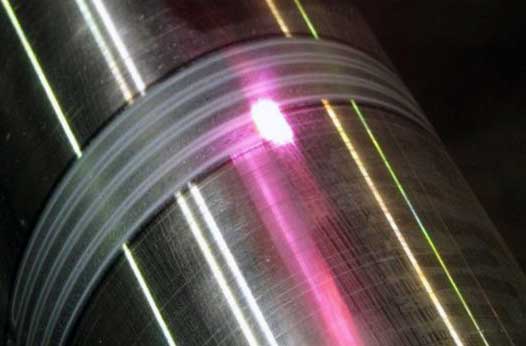

Laser hardfacing of a Ball Mill Wear Ring

with 60% tungsten

|

Call or email Laser Cladding Services to discuss your laser hardfacing project.

|

Laser Cladding

Laser Cladding

Laser Hardfacing

Laser Hardfacing

Laser Heat Treatment

Laser Heat Treatment

Capabilities

Capabilities

Contact Us

Contact Us

|